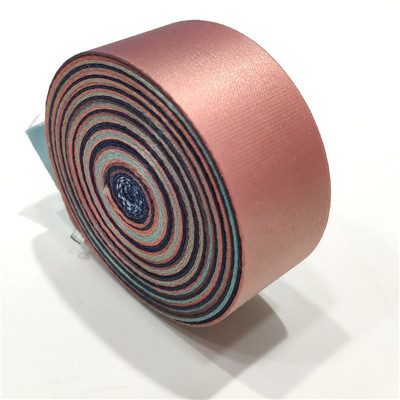

Sublimation printing polyester nylon webbing

| Product Type: | Printing webbing |

| Material: | 100% Polyester |

| Color: | picture display or customize |

| Technics: | Jacquard |

| Feature: | Eco-Friendly |

| Thickness: | 0.9-1.4 mm or to be customized |

| Width: | 2cm, 2.5cm, 3.8cm, 5cm or customized |

| Package: | 50yards/roll,45meters/roll |

The most widely used printing on the webbing is silk screen printing, the full name is screen printing. Various patterns, patterns, English letter logos and other graphics are processed on the surface of the webbing to form the desired silk screen effect.

1. Screen printing

Screen printing is to stretch silk fabric, synthetic fiber fabric or metal mesh on the screen frame, and use the method of hand engraving paint film or photochemical plate making to make the screen printing plate. Modern screen printing technology uses photosensitive materials to make a screen printing plate (make the screen holes of the graphic part of the screen printing plate through holes, and the screen holes of the non-graphic part are blocked. live). During printing, the ink is transferred to the substrate through the mesh of the graphic part through the squeeze of the squeegee, forming the same graphic and text as the original. The screen printing equipment is simple, easy to operate, easy to print and plate making and low cost, and it is very adaptable and easy to print.

2. Thermal transfer

This process has low cost and good effect. It has an absolute price advantage when printing dot patterns, and the thermal transfer lanyard is absolutely environmentally friendly, so it is also widely loved by customers and friends.

Working processing display;

Workinga shop apart shows;

Packaging and delivery;

Selling Units: Multiple of 50 yards for one roll,

Package size per batch:15X10X15 cm

Gross weight per batch:0.050 kg

Package Type;1)50yards/roll,one roll/pastic bag 2)20 rolls/carton 3)As your requirement

Lead Time:

| Quantity(Yards) | 1 – 3000 | >3000 |

| Est. Time(days) | 7 | To be negotiated |